GE-Digital, the industry leader in energy software, today announced a new version of Profitable Plant Applications, its MES platform used in thousands of process, discrete and mixed manufacturing plants worldwide.

Part of Proficy Smart Factory software portfolio, Proficy Plant Applications 2023 can help manufacturers reduce downtime and improve operator performance with innovative new capabilities for discrete manufacturing, a no-code/low-code environment, and out-of-the-box applications for modern user interfaces, as well as zero-time web client updates.

Available for both on-premises and cloud-based installations, Proficy Plant Applications is GE Digital's MES software for which the company has been positioned by Gartner as May 2022 Magic Quadrant Leader for manufacturing execution systems.

Last month, GE Digital also received the grade of Leader in the Manufacturing Execution System Competitive Ranking of ABI Research.

“Our leadership in the MES industry is built on customer-driven innovation that delivers business-first outcomes,” he said. Richard Kenedi, General Manager of the Manufacturing and Digital Plant division of GE Digital. “Our MES software helped a paper company save $4 million in one year, including $1,25 million from a waste reuse application, an automotive company reduce inspection costs by 40% and a beverage company to decrease bottling line downtime by 39%. These are real results that our MES has achieved around the world, helping to improve customer performance and competitiveness.”

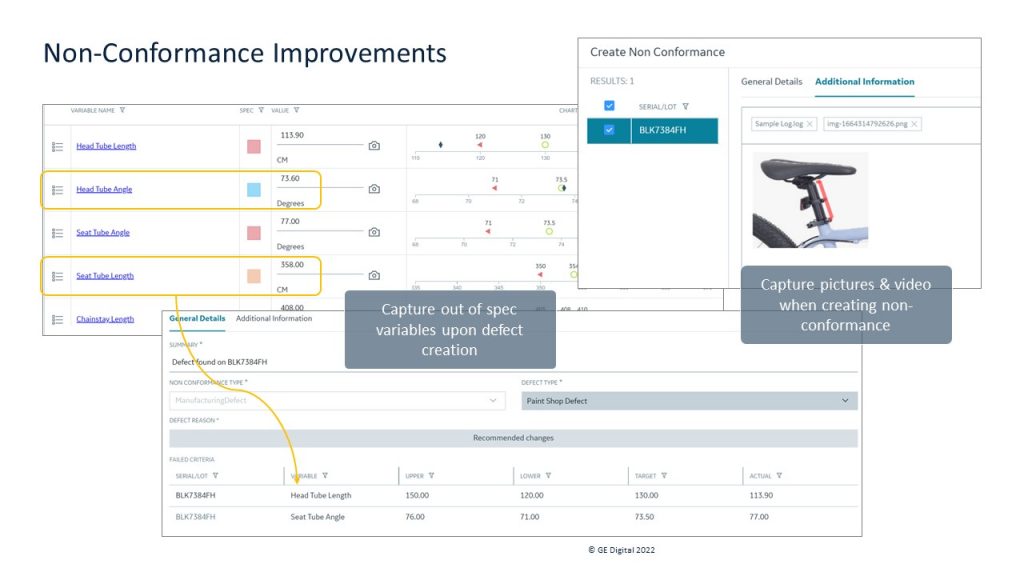

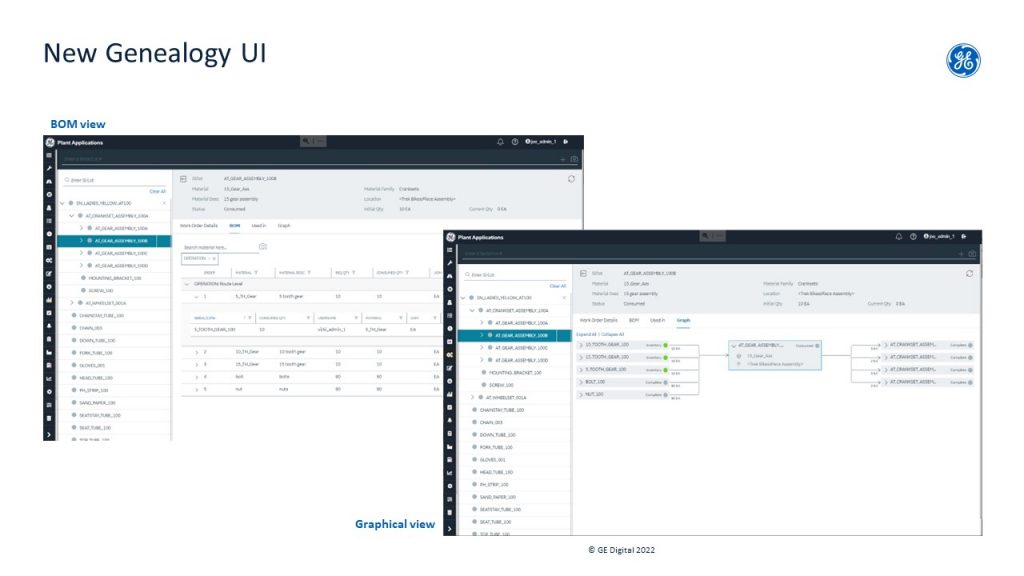

Proficy Plant Applications 2023 can help reduce costs, maintenance and training by providing a single enterprise-wide MES solution that supports process, discrete and mixed manufacturing. The new release further expands support for discrete manufacturing with significant improvements to nonconformance management, bill of materials (BOM), and product variable functionality.

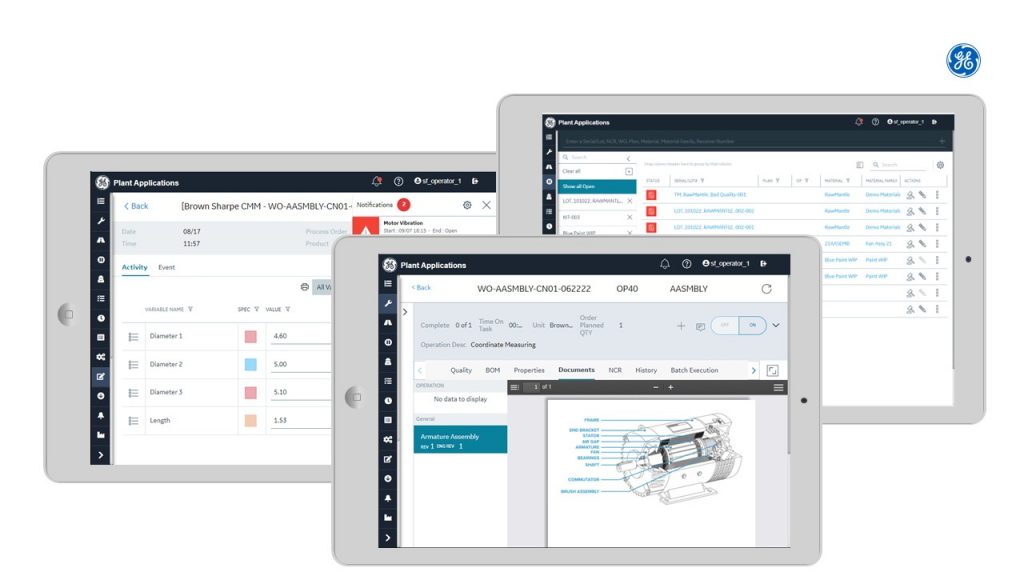

To improve decision-making and operator performance for greater efficiency and quality, Proficy Plant Applications 2023 features both new out-of-the-box web UIs as well as a no-code/low-code environment for configuring dashboards and operational intelligence app. Easily and fully user-customizable, Proficy Plant Applications screens enable connected workers to have a single contextual pane of glass for real-time supervisor and operator information, available anywhere through modern web and mobile technology. Additionally, the new version can improve the user experience by boosting application performance through lower system memory requirements and a smaller footprint.

The new release also accelerates time to value with faster startup and continues to provide architectural flexibility, scalability, and cost savings while supporting both on-premises and cloud-based deployments.

Proficy Plant Applications comprises four modules: Efficiency management, Production management and monitoring, Quality management e Batch Analysis. The software is used in thousands of different manufacturing sites around the world, including major manufacturers of food and beverage, non-food consumer packaged goods, automotive, pharmaceutical, aerospace, chemical, heavy equipment and others.

Register at Proficy webinars 2023 by GE Digital to learn more about Proficy Plant Applications 2023 and others Proficy software.