Today there is a lot of talk about the Digitization of the production company (Industry or Utility), especially from an Enterprise 4.0 perspective: this also allows you to take advantage of tax incentives that make the investment more attractive from a financial point of view and speed up its ROI ( the rate of return on investment).

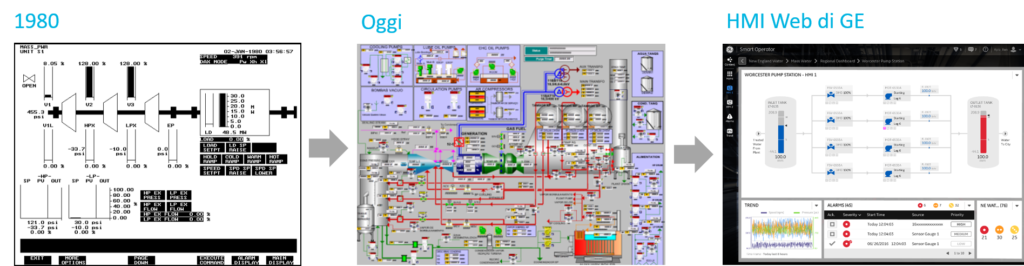

Enterprise 4.0 and Digitization are updated terms for topics that we at ServiTecno have been using and dealing with for over 30 years: we started in 1985 to offer the first versions of the software SCADA “The Fix”, and since then our aim has been to collect data on the plant and connect machinery and plants on the factory network and convey data and information to all the functions which, by using them, can improve the Company's production, quality, efficiency and safety.

Over time we have evolved technologies and products that we offer to the market, following the requirements and wishes of our customers who use systems that have software on board every day iFix and Historian that we provided over time: they were approx 10.000 iFix licenses installed in Italy at the beginning of this millennium.

Today we can estimate that SCADA stations (Client+Server) installed and operating in the Italian plants are three times as many. What allowed the coupling SCADA iFix+Historian of GE Digital to become a standard used wherever it is necessary to have the system “under control”?

Many of our Customers, especially where there are machinery and plants to manage where reliability is one of the essential requirements, tell us that still today the solidity and performance of iFix are a "security".

Some of the intrinsic characteristics of iFix still remain unique and unmatched by almost all similar products present in a crowded market such as that of factory automation and process control software.

Surely for this and for many other reasons the coupling GE Digital's iFix+Historian is often the first choice in installations of regulated industriessuch as sectors Pharma, Life-Science, F&B, O&G, Power, etc.

In addition to the well-established reliability and resilience, there are some aspects of the solution iFix+Historian which allow it to excel and be a solid and secure solution for any industrial application, chosen without compromise by IT, OT, CIO and CIoTO managers:

- iFix Web HMI, provides a high-performance HMI according to the dictates of Impresa4.0 which, by accessing all data sources, improves the vision of the entire plant and allows operators rapid replieseiFix + DreamReport: within the solution.

- iFix, DreamReport makes it the most versatile historical and real-time analysis platform (Big Data + Analytics according to Industry4.0) available today.

- iFix + Win911: WIN-911® is the real-time alarm notification platform for iFix (or with other SCADA systems for plant monitoring) with the aim of alerting personnel in the event of anomalous conditions, even remotely and using mobile devices.

- iFix+IGS: with Industrial Gateway Server, iFix, in addition to managing all OPC and OPC-UA communications towards the plant, opens up to the Industrial IoT world, for reliable and secure communications.

- iFIX+Historian in Redundant architecture, in High Availability (HA, High Availability) and FT (Fault Tolerant): where it is necessary to guarantee up to 99,9999% of uptime, without loss of data and control.

- iFix in Secure-By-Design architectures: following the dictates of standards for ICS/OT Cyber Security (such as IEC62443, NIST Sp800-82, ISO2700X, etc.) with the advice of ServiTecno experts.

Here are some of the reasons why iFix+Historian is today the "solution" of reference for systems and applications in plants from an Industry/Enterprise 4.0 perspective, with the tranquility of a choice that has allowed thousands of companies to be competitive and "already digitized" over the last three decades.

Applications in the Process Automation field are rapidly changing appearance and nobody can know what new strategies will be set up: however it is easy to understand how systems developed with standard market platforms can be more easily connected to third-party solutions, compared to custom applications created ad hoc.

For this reason, relying on General Electric means choosing continuity, bonding with a brand that will never fade.