1. What is IoT really?

THEIoT it is simply one evolutionary stage of the Internet: physical machines (objects, things) fully participate in the global network, producing and consuming information and communicating as equals with other devices, applications and human beings. As is often the case, the early days of the IoT were experimental, with much of the work done in the labs, academia and research departments of the most advanced industries.

As the IoT became available to the market, the many have considered the IoT a threat. Horror stories are known about botnets of cameras and cold rooms or backdoor access to customer data via the control system of the aquarium in the company lobby. However, we must consider that the IoT is still an IT system to which the IT and cybersecurity best practices that we have developed over the decades apply equally. We see it when it comes to monitoring: zero-day vulnerabilities that emerge in many cases are not specific to IoT, but stem from other systems. Using frameworks to test known threats and applying anomaly detection to find new vulnerabilities is as critical in the IoT as it is elsewhere.

THEIoT is also an opportunity to lead businesses towards digital transformation, and not only. The networking, programming and analysis skills of IT specialists can also be re-deployed in the IoT, shifting the focus from IT information technology to OT operational technology. Even the IoT and the Industrial IoT see the IT-OT convergence with the use of the cloud, edge and the Internet towards the interaction between technology and cultural and economic progress.

2. Where to put IoT/IIoT data?

Measurements and events are at the heart of the whole IoT world and therefore to be considered when talking about solutions to be used in the implementation of systems in which IoT is one of the factors. These data types are basically time series of data and indicate the performance and functioning of the system itself. Therefore, it is essential for the monitoring, management, optimization and marketing of an IoT investment that the instrumentation of each machine, plant, process allows the communication, collection and archiving of such data to be easily retrieved, analysed, aggregated and used.

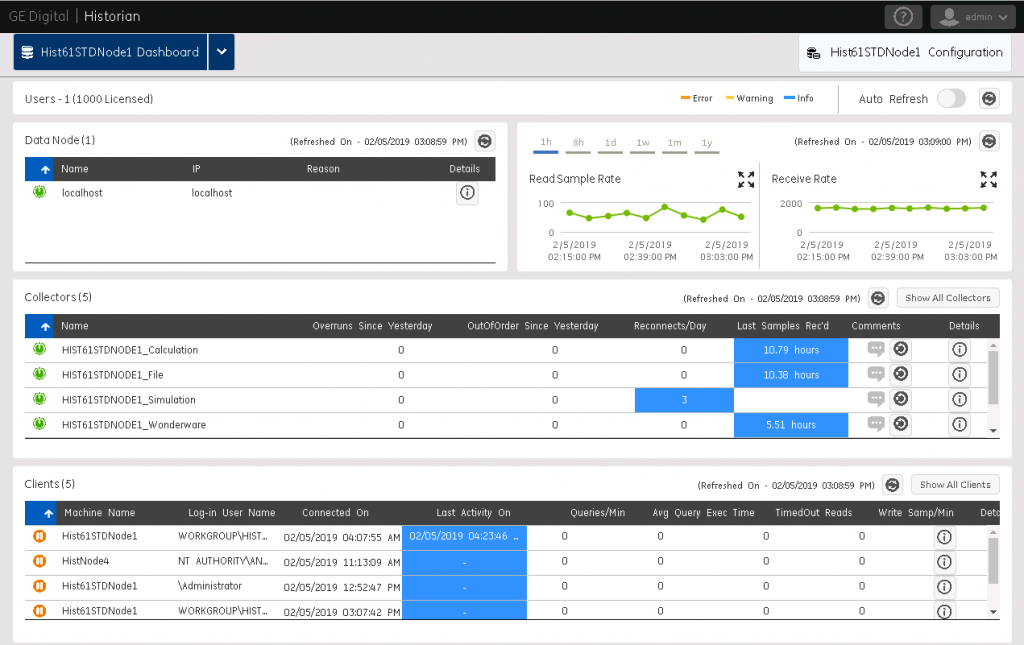

Unfortunately, many IoT projects don't start with this in mind. Many standard IoT platforms start out with some form of generic database, something meant for storing documents or graphics sometimes a simple market-based or open-source relational database. While these databases can store and analyze with timestamps, sometimes they cannot bear the volumes and performances required in production or they run out of power for really demanding use cases. Conversely, Historians used as a database for time series data have specific functionality for the solution and in the back-end architecture (Historians rarely use tables) both in the scripting languages provided.

Planning from the start of using a Historian as a core component of the IoT solution stack can make all the difference, allowing for natural, modular scale-up and can avoid costly reconfiguration later in the development process. It's essential to consider how the Historian will be configured, how it will operate in a distributed, on-premise or cloud environment, and whether it will lock us down with a specific cloud vendor or geographic region. The specification should therefore stipulate that the data time-series database enables the IoT/IIoT solution to be open and scalable without hindrance.

3. What is data used for and how is it used in IoT solutions?

Monitoring: Keep an archive of measurements over time and use that data to understand trends and how they are related. Monitoring can include, for example, counting how many times a CPU has reached 100% in 24 hours or monitoring the increase and decrease in temperatures, pressures, levels, flow rates of an industrial process, aqueduct or an energy source. Monitoring can be done visually, via dashboard tools but also automatically and unattended via machine learning applications and other AI analytics processes.

Optimization: For improvements with an IoT/IIoT system, it is necessary to define the relationship between related time series streams and model those relationships in models for simulation (sometimes called digital twins). You can then use these models to detect and remove operational inefficiencies, improve performance. Optimization takes tracking one step further and overlays additional context, which considers time series data in a more macro sense, thanks to references with benchmarks.

Applying statistical and machine learning techniques in similar contexts for these groups of time series opens the door for causal analysis, what-if analysis, algorithmic simulations using AI, and more to anticipate and prevent shutdowns and breakups.

Marketing: one of the great promises of the IoT is that it will be an enabling factor of “servitization”. As IT moves to the cloud, it moves towards consumption-based business models. Here you pay for compute based on CPU time, storage based on disk usage over time, and network based on bandwidth usage over time. The “over time” part should be clear: services like this monitor and track consumption in a time-series database and use those metrics to calculate your bill. Similar “pay for what you use” models are finding their way outside of cloud providers, such as in transportation, insurance and more. When you use a service, the rental of a means of transport or an asset that you pay for by the time or by the kilometre, there is the IoT behind it and a time series database at work behind the scenes.

4. What are the other technologies for Digital Transformation in manufacturing IIoT?

The most important thing to understand is that IoT alone makes little sense. The IoT is one of the technologies that can generate value and results if implemented together with others and if well organized in a Digital Transition plan. Time-series databases don't have to become data silos—they're a vital component of both IoT solution architecture and success—but it's critical to understand how the entire ecosystem can come together in one powerful solution.

IoT solutions almost always start with a machine-to-machine (M2M) application. At an industrial level in an “Industrial Internet of Things”, IIoT, M2M almost always means a device, an industrial control system, SCADA or an application that takes data from PLCs or other automation devices connected via gateways with brokers that do as a bridge between industrial protocols (OPC etc.) and those of the IoT (MQTT etc.). Naturally, the entire connectivity chain and related communications must take place in a safe and secure manner.

Then, as we said, choosing a Historian database that integrates easily with these platforms is an essential step.

Understanding what happens in production and on plants and developing interventions that solve problems and improve efficiency and productivity is one of the most critical phases in the path of using IIoT towards digital transformation.

To respond to this need, it is important to have tools that provide a UI User Interface that is simple to implement and effective to use, a modern and centralized environment that allows you to configure intelligent industrial applications to improve connectivity, aggregation and data visualization, in a web environment and on every device, and improve processes, also in a collaborative key.