What does MDT Autosave do?

MDT AutoSave provides timely version control (in practice it acts as a repository for all the applications that "move" the system), backup, historical tracking, verification and registration of authorizations following changes, electronic approval and audit trail, automatic detection of changes and disaster recovery for: PLC, CNC, SCADA systems, robots, welders, drives, workstations, HMI and documents and any other applications.

MDT AutoSave supports more automation devices than any other change management software in the industry, including devices/software from ABB, AVEVA, Bosch Rexroth, DENSO, Emerson, FANUC, GE, KUKA, Mitsubishi, Omron, Rockwell, Siemens, Schneider Electric and many more.

MDT AutoSave provides the following features:

- Un revision archive of the previous settings of applications.

- Has ability to detect and track changes and variations of process.

- Provides tools for document the changes and make them visible to users.

- It conveys information in one history of who made the changes, when and from where they were performed.

- Moderates secure access for users and workstations.

- Automatically captures and saves program updates to the designated server as they change.

- Check permissions to perform operations.

- Provides a dedicated change management repository for off-network and remote devices as well.

- It supports a wide range of devices and any PC based application.

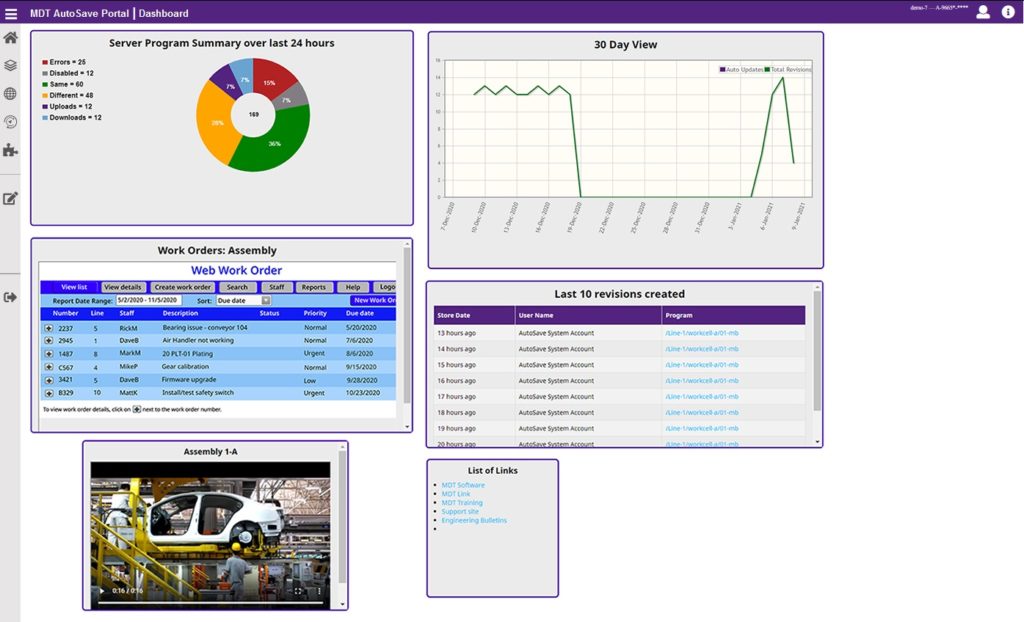

- Provides real-time monitoring through an online portal.

For manufacturers and utilities with disconnected devices (in remote areas) and non-networked devices in the plant, MDT AutoSave provides the following change management features:

- It allows you to track and analyze changes made to a large number of non-networked devices and easily synchronize them directly via server.

- Enable system integrators and offsite development teams to work on programs without direct device connectivity.

- It can synchronize/approve many changes with a single command.

- It allows you to view a history of changes made on each device.

MDT also provides a decision support portal: AutoSave allows users to view all plant activity, including program activity, OEE and results (also compared to forecasts) and much more. This information vital to plant efficiency is accessed from a single web interface that can run on traditional PCs, laptops and mobile devices.

What problems does it solve?

MDT AutoSave protects intellectual property on the Plant Floor, facilitating a proper recovery following hardware failures, errors and sabotage.

Have you made a change to the software that you wish you hadn't made?

MDT AutoSave Change Management software allows you to “undo” the change and restore the previous configuration in seconds.

Do you have a backup of the latest version? how much would it cost you to lose the only copy of the device's program?

MDT AutoSave ensures that if a program is lost due to device failure, power loss, etc., the most recent copy of the program logic can be automatically recovered so plant operations can be restored quickly and correctly.

Not sure if the program you're running is the right one?

MDT AutoSave can assist in verifying that the running program matches the designated reference application. This allows you to detect and identify changes that may have been unauthorized, thus protecting your process, people and equipment.

Some real examples of the problems you could face if you don't have the right technologies for Change Management and Version Control…

1. A US plant of one of the world's largest automakers experienced a PLC failure and the last program configuration was lost, meaning an older version of the device's program was used. Extensive editing was required to match the old program data to the required processes. Finding the old program and making the necessary updates resulted in 6 hours of lost production. The plant stated that if they had AutoSave at the time of the PLC failure, the reduced downtime would have paid for the system in that one downtime.

2. A manufacturer of specialty metals received new material specifications from the customer that required a change to the PLC programming code. The change was made to the master copy, but it was not uploaded to the device itself. Therefore, the stored program code did not match the code running on the device. The code that ran on the device still followed the "old recipe", causing 3 months of incorrect production. The product had to be recalled, reproduced and sent back: Autosave would have carried out the checks on the application used, avoiding the problem.

Regulatory requirements:

MDT AutoSave is especially recommended for Food & Beverage and pharmaceutical manufacturers due to regulatory requirements. These facilities must comply with stringent regulations and standards that require the ability to track process changes and ensure that processes themselves have not been altered without approval or documentation.

MDT AutoSave contains tools that can significantly streamline the change approval process in a validated environment and help ensure proper change processes are followed including through the use of AutoSave's electronic signature and the ability to create approval flowcharts.

Computer security:

Every manufacturer and utility is faced with the ever growing and ever changing threat of cyber attacks (or incidents). One of the most effective and common methods of attacking a manufacturing facility is to gain access to control systems by “entering” the Plant Floor. MDT AutoSave helps manufacturers prepare for an attack, detect unauthorized changes, and quickly recover from an attack.

AutoSave saves a copy of each program revision in a central repository. Access to folders and programs is managed through a flexible system of privileges: it also detects changes made outside the change management system by comparing the last copy of the program on file in AutoSave with the program running on each device to identify any differences. If differences are found, operators are notified with an email highlighting the discrepancies.

It is therefore possible to quickly identify, recover and list from unauthorized changes: with an archive of all program revisions, it is possible to quickly restore the last approved program after an unauthorized modification.

Who are your customers and your fields of application?

Automation devices and their logic programs are expensive to develop but vital to the operation of many manufacturing and utility facilities. Therefore, any plant that uses these assets must have adequate safeguards to protect and manage the change of these technologies. The main industries requiring MDT AutoSave are:

Automotive industry: Safety and reliability are the key factors in the automotive industry. Global competition has been around for many years, and every manufacturer is looking for ways to maximize production uptime while avoiding untracked changes in automation equipment that could lead to costly rework or recalls. MDT AutoSave is part of the change management and disaster recovery infrastructure in automotive plants that produce millions of vehicles annually. In fact, it's the corporate standard for some of the world's largest automakers such as Honda, Chrysler, Toyota, and many more.

Food & Beverage: MDT AutoSave is part of the change management and control infrastructure that helps safeguard operations from errors and costly downtime. In the event of a device failure, the correct program can be accessed and downloaded to the device so that operations are resumed quickly, while AutoSave's change tracking and notification features ensure that unknown or unauthorized changes do not compromise risk people, processes or products. Food and Beverage customers include MARS, Abbott Nutrition, Proctor & Gamble, Nestle Purina, General Mills, Arla foods, Coca Cola and many more.

Life Sciences/Pharmaceutical: Due to heightened regulatory scrutiny over the life sciences industry, manufacturers must be confident that their processes have not been altered without approval or documentation. MDT AutoSave is part of the change control and audit infrastructure that ensures regulatory compliance. Tracking changes in PLCs, HMIs, workstations and more is an integral part of protecting your processes, people and end products. AutoSave's audit trail, electronic signature, and workflow approval support, along with its internal security capabilities, have long been beneficial to regulated industrial sites in meeting FDA requirements, such as: Hospira, Johnson & Johnson, GlaxoSmithKline, Baxter and others.

Mining & Metals: Mining is often characterized by harsh environments and harsh operating conditions. Such conditions require special attention to safety and health, as well as continuous monitoring of environmental issues. MDT AutoSave is part of a best practice change management and audit infrastructure required to maintain a high standard of safety in mining operations. Nearly all above and below ground operations in a mine are controlled by a variety of PLC and SCADA systems and even some DCS systems. Such operations often require regular program code changes to be made due to evolving manufacturing issues. MDT AutoSave ensures the existence of proper rollback/recovery data by tracking changes in these PLC and SCADA programs and providing change notification for customers such as: ArcelorMittal, Rio Tinto, Assmang, BHP Billiton and others.

Petrochemical: MDT AutoSave is part of the change management and control infrastructure that helps refineries and chemical plants identify and eliminate hazardous situations while increasing productivity. AutoSave ensures that adequate rollback/recovery data exists, while providing an audit trail and change notification. This can be invaluable in understanding what program changes are being made, why and by whom, so that people, processes and equipment are protected. AutoSave's unique features, including internal security capabilities, have long served petrochemical companies looking to better manage operational changes. Some clients include: Chevron, Johnson Matthey, Pacific Gas & Electric, Marathon Oil and others.

Utilities: From electric utilities to water and wastewater facilities, there is growing concern about the potential for inadvertent or malicious changes in automation control that could lead to dangerous situations. In addition to providing data backup and recovery in the event of device failure, AutoSave can compare the program running on the device to the latest revision stored on the server or technician's laptop. AutoSave's support for off-network operations is especially valuable for utilities with remote resources, so that all program changes made in the field can be analyzed and synchronized with the server at the plant. MDT has a significant number of clients including: The Water Corporation of Australia, South West Water, Aguas Nuevas, and many other municipal water and electricity companies around the world.

MDT also serves a wide variety of specialty manufacturers, such as airport and other transportation suppliers, paper manufacturers, electronics manufacturers, and more. This diverse range of customers all have a need to track and manage changes in their automation environment involving a diverse range of products.