DataHub use case

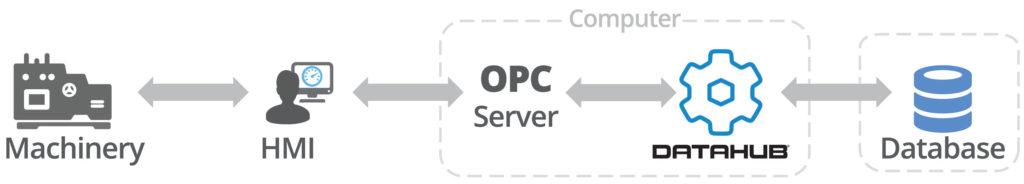

The management of a large North American textile company wanted to collect data on machine performance. They were concerned that every time a machine stopped, someone had to manually collect all pertinent information: time, product type, operator and other parameters. The HMI they were using to control the machinery had an OPC server, so they decided to find a way to use it to automatically collect the data they needed.

A web search led them to the Cogent DataHub. Within hours they were able to connect the DataHub to their data, and start record the data they needed in a database. Now whenever a machine stops for any reason, they get an instant log showing the time it stopped, the fabric produced, the operator on duty, and other information. Whenever they need to change these parameters, they can simply reconfigure the DataHub to log other data arriving through the HMI. The resulting ability to evaluate the performance of both machines and people has led to significant cost savings for the company.