Managing batch production is not simple.

With a robust set of tools, an open architecture, and an intuitive graphical interface, Proficy Batch Execution makes a strong contribution to the variation of a more efficient and constant production environment.

È possible to run batches for the production of a specific quantity of final products on any line, according to the specifications defined to minimize variations and maximize returns.

Also you can implement the form GE Batch Analysis (module of GE Plany Application), tightly integrated with GE Batch Execution, allowing you to better analyze and control variation within batches.

Graphic modeling

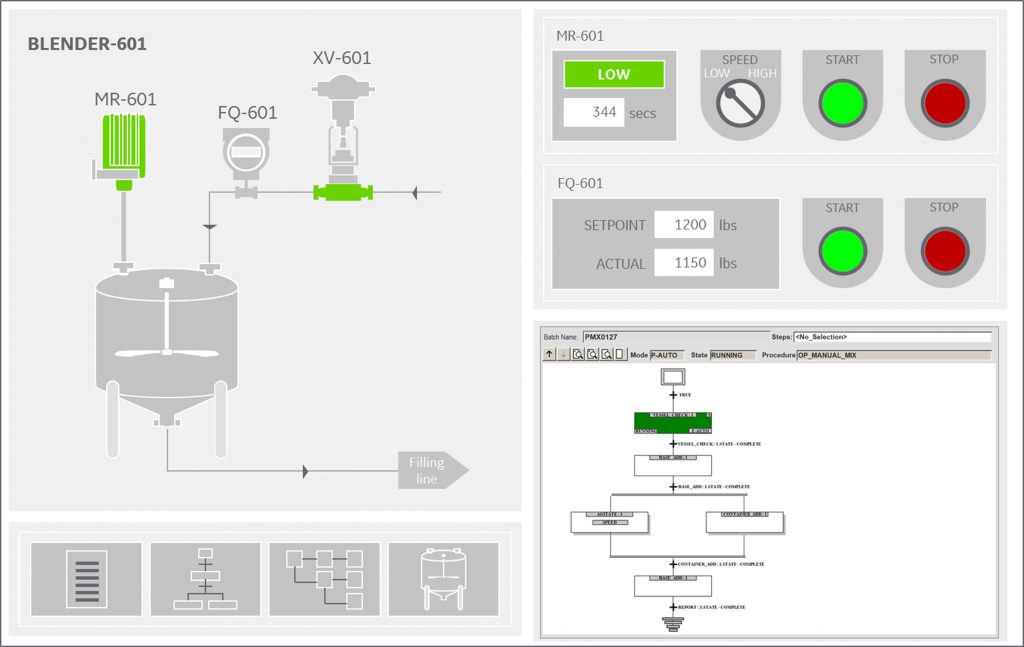

Modeling according to ISA S88.01 of production activities allows to define areas, process cells, units and phases in the Batch Execution workspace, a simple and class-based graphical environment, which allows you to navigate directly to the process control without having to have any database.

The Batch and SFC ActiveX control commands show the 21CFRPart11, Proficy Batch Execution dialog, which appears when an operator changes a parameter.

Graphic recipe editor

The graphic editor allows you to create recipes in the form of a simple spreadsheet; a single click allows the system to automatically convert them into sequential function diagrams according to IEC 61131-3.

Class-based recipes allow for reuse of recipe components and can be scaled to match plant capacity at run-time.

21CFRpart11

Verification at entry points using electronic signatures enables auditing and version control of plants and recipes. The Batch Execution system provides centralized archiving of electronic logs with encrypted store and forward technology that automatically provides an audit trail of run-time and configuration; passwords and user IDs are managed centrally via a Windows-based security system.

ActiveX library

They allow you to view and interact with existing processes for pools from any ActiveX object container. These include the Batch list, a sequential function chart view, unit association, prompts for operators, adding batches, manual phase control, recipe list, active phases and the 'list of batch alarms. This provides operators with excellent visibility into batch activity.

Batch Direct

it is an intuitive interface between Batch Execution and the phase/system logic present in the controllers; supports the Programming Logic Interface (PLI) programming logic interface function and offers a customizable approach to implementing batch functions with existing control systems, without the need to reprogram complex control logic.

Batch production S88 standards

GE Batch Execution separates the operation (the phase) of the plants from the procedures (recipes) used to make the products; the processes used for the latter are therefore defined in GE Batch Execution and the relative modifications do not give rise to variations in the control system.