There are many different types of businesses and companies in the machine and equipment manufacturing (OEM) industry, but one challenge is always the same: the market is highly competitive.

Each generation of equipment offers lower prices and performance improvements over previous generations. Product design, engineering and management departments must constantly evaluate the trade-offs between new technology improvements and associated cost increases as they bring new designs to market.

Automation has been an integral part of equipment design for many years, new concepts like digital transformation, smart manufacturing, industry 4.0 and industrial internet of things (IIoT) are more and more applied in the manufacturing world to offer competitive advantages.

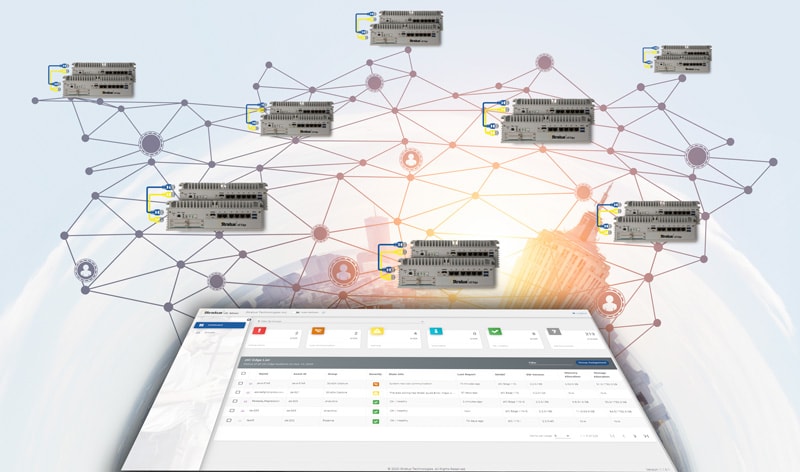

This white paper focuses on what machine and equipment manufacturers (OEMs) can do to take advantage of these new concepts and how Edge Computing can meet both their specific needs and those of their customers.

Smart factories need (even) smarter equipment

DOWNLOAD THE WHITE PAPER

PDF legend:

- Edge Computing platforms offer new opportunities to improve performance for manufacturers of industrial machinery and equipment

- Smart factories and smart manufacturing need smart machines

- What is Edge Computing?

- Edge Computing enables the use of intelligent machines and equipment

- Edge Computing Features for Machine and Equipment Builders

- Support for existing automation and control applications

- Modify and update existing control applications

- Added new analytics and digital transformation applications

- Support for OT/IT convergence

- New earning opportunities

- robustness

- Cost reduction

- Edge Computing platforms must be simple, secure, self-contained

- Simplicity

- Protection

- Autonomy

Smart factories need (even) smarter equipment

DOWNLOAD THE WHITE PAPER