The AVAILABILITY of a production plant is today recognized as one of the most important KPIs in the process environment: but how much does the DOWNTIME of the systems cost your customers annually? Find out with our “Cost of Downtime Calculator”.

The UPTIME is closely linked to the technologies that govern the plant in standard situations but it also has to do with the time necessary to restore the optimal situation in the event of unscheduled downtime. The two proposals below go exactly in this direction.

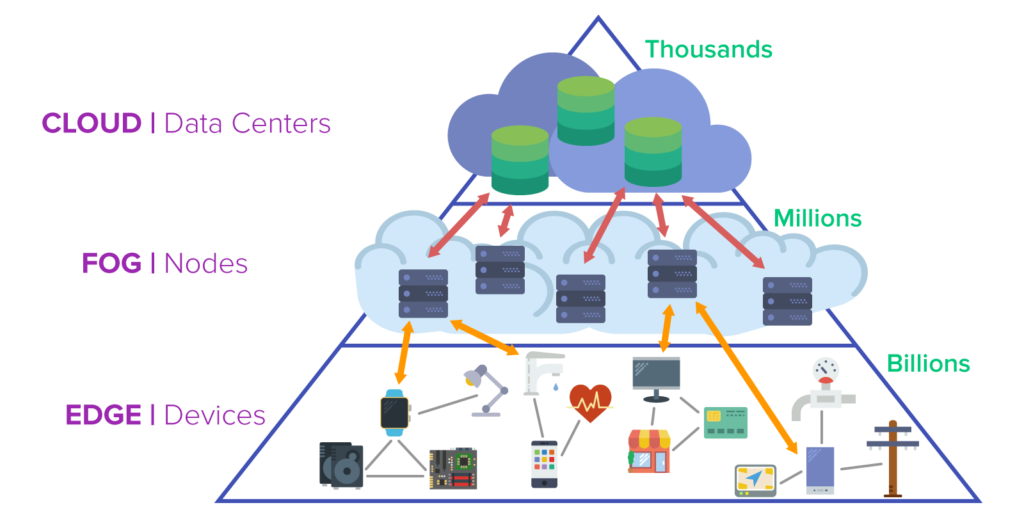

1) How to keep up with the evolution of Edge Computing to gain a competitive advantage

Many companies are evaluating existing Edge Computing systems to improve the methods of acquiring and processing data resulting from the explosive growth of devices connected to the Internet: we are no longer talking about simple boxes that simply act as a bridge, but about devices that can give certainties on the topics listed below.

- High performance (of storage and management of virtual machines for ICS systems): high performance about capacity of computing and storage in order to "host" inside both the SUPERVISION SYSTEM that the PROCESS DATABASE. In this way it is possible to send already “processed” and useful data to the CLOUD for an advanced analysis.

- High Availability (a level of redundancy that guarantees a UPTIME greater than 99,99%): architectures capable of guaranteeing HIGH AVAILABILITY (and in some cases FAULT TOLERANCE) and keeping supervision available (and its visualization via client)

- A secure connection to the CLOUD: these are devices designed to let only authorized data and commands go out (and enter). So we're talking about an active filter both incoming and outgoing, useful for protecting both systems and architectures in the CLOUD.

- A point of IT/OT CONVERGENCE reliable and easily manageable: theIT is already familiar with the EDGE concept, but often little knowledge about what is underneath (PLC, SCADA and ICS systems in general).

With these devices it is possible to create a unique connection and provide "upper floors" INFORMATION instead of PURE DATA (RAW); moreover they are easily replaceable, it is enough to always have a backup of the applications used (and with some products such as the ztC of Stratus you don't even need that as they align completely automatically)

With these devices it is possible to create a unique connection and provide "upper floors" INFORMATION instead of PURE DATA (RAW); moreover they are easily replaceable, it is enough to always have a backup of the applications used (and with some products such as the ztC of Stratus you don't even need that as they align completely automatically)

ZTC EDGE by STRATUS TECHNOLOGIES is the solution proposed by ServiTecno for “Plug & Play” High Availability: quick installation and 99,99% Availability guaranteed.

A management tool, the ztC Console, simplifies the setup, configuration and management of virtual machines. Self-protection and self-monitoring features help reduce unplanned downtime and ensure maximum availability in business-critical industrial applications.

2) And the restart? How long does it take to restart after an unscheduled Downtime?

One repository for all “OK APPLICATIONS”: this is how restarting after an accident is shortened thanks to MDT AUTOSAVE.

It goes without saying that the more expensive production is, the more our RTO will tend to 0 (it is not possible to have interruptions): this is especially true for regulated industries and critical processes.

Platforms for Change Control and Version Monitoring, address a critical aspect of security that is in no way treated when it comes to the most talked-about topics in the field of cyber security (editor's note: "data privacy" and "anomaly detection"): the intellectual property contained in the applications that manage the process (and not just that).

Disaster Recovery Plan: Do you have one? How should it be set?

The RECOVERY TIME OBJECTIVE represents the time in which our system becomes efficient again, basically the tolerated DOWNTIME. It goes without saying that the more expensive production is, the more our RTO will tend to 0 (it is not possible to have interruptions): this is especially true for regulated industries and critical processes.

The question to ask is therefore: ONCE THE ATTACK NOW, HOW LONG DOES IT TAKE TO START AGAIN? DO I HAVE A PLAN B?

Here is ServiTecno's “plan B”…

Platforms for Change Control and Version Monitoring address a critical aspect of security that is in no way treated when it comes to the most talked-about topics in the cyber security field: the intellectual property contained in the applications that manage the process (and not only that).

The industrial sector and in particular the manufacturing sector is the second most targeted sector by cyber crime and many attacks are successful due to the numerous vulnerabilities present in the production environment.

Regardless of how a threat occurs, these platforms can:

- GET READY: Protect the intellectual property of your APPLICATION. Autosave saves a copy of each program revision in a central repository. Access to folders and application backups is managed through a flexible privilege system.

- DETECTS: Detects unscheduled changes that are made on different systems and devices. It is important to be able to compare the last saved and validated copy of the program with the one physically running on each device to identify any differences. If differences are found, the appropriate people are alerted and variation management begins.

- RECOVER: Quickly recover from unauthorized changes. With an archive of all program revisions, you can quickly restore the last approved program after an unauthorized change.

Our offer for “Zero Downtime”